| ‘C’ Type Press |

|

‘C’ Type Presses are generally used for Punching, Embossing, Blanking, Compacting, Coining & other general applications. These presses can be made with die cusion and also can be made as per customer’s requirement.

Capacity : 6.3 – 100 Tons

Stroke : 50 to 600 mm

Daylight : 300 to 1000 mm

Working Area : 250 x 250 to 1200 mm x 1200 mm

Operation : Push button in inch / single cycle

|

|

| HYDRAULIC SCRAP BALING Press |

These presses are designed for processing plastic, ferrous and non-ferrous scrap in all forms. They are available in different models which helps the user to select the machine as per their requirement. They can also be customised as per customer's specifications.

| Sl.No. |

Capacity |

Chamber Size |

Bale Size |

| 1 |

40 M.T. |

600 x 200 x 1000 |

200 x 200 x 200 |

| 2 |

60 M.T. |

700 x 250 x 1100 |

250 x 250 x 250 |

| 3 |

80 M.T. |

800 x 275 x 1200 |

275 x 275 x 275 |

| 4 |

100 M.T. |

800 x 300 x 1250 |

300 x 300 x 250 |

| 5 |

125 M.T. |

900 x 300 x 1300 |

300 x 300 x 300 |

| 6 |

150 M.T. |

1000 x 350 x 1400 |

350 x 350 x 300 |

| 7 |

200 M.T. |

1200 x 400 x 1500 |

400 x 400 x 300 |

|

|

| SOLDIER EXTRUSION PRESS |

| These presses are used to extrude Zinc, Lead, Tin based alloys and these are mainly used in soldier wire extrusion.

CAPACITY : 250 Tons

|

|

| Rubber Moulding Press |

|

These presses can be made of closed frame /4 PillAr construction. These are used to mould Seals, V-belts, Automobile Rubber Components, Flap moulding etc. Multi daylight / Multi station presses with PLC control are used for heavy production.

Capacity : 25 – 600 Tons

Stroke : 200 to 800 mm

Daylight : 300 to 1200 mm

Working Area : 300 x 300 to 1200 mm x 1200 mm

Operation : Push button in inch / single cycle

|

|

| Close Frame Press |

|

These are heavy duty presses and are used for deep drawing, Compression moulding Forming, Blanking and many more applications, Die Cusion arrangement can be provided for cusioning effect.

Capacity : 100 – 1000 Tons

Stroke : 200 to 1200 mm

Daylight : 300 to 1500 mm

Working Area : 400 x 400 to 1600 mm x 1600 mm

Operation : Push button in inch / single cycle

|

|

| Four Pillar Press |

These presses can be made of 4 Pillar construction. These are used to Punching, Embossing, Blanking, Compacting, Coining & other general applications. These presses can be made with die cusion and also can be made as per customer’s requirement.

Capacity : 100 – 1000 Tons

Stroke : 200 to 1000 mm

Daylight : 300 to 1200 mm

Working Area : 300 x 300 to 1200 mm x 1200 mm

Operation : Push button in inch / single cycle |

|

| HOT LOG SHEAR |

|

|

The Hot Log Shear is used to shear the log heated in a furnace to the required length. the length of the billet can be adjusted as when required as per the requirement of the die being extruded. The extrusion recovery is considerably improved compared to the conventional Billet cutting Machine used.

|

|

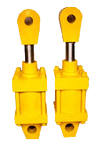

| Hydraulic Cylinders |

|

Types : Single Acting, Double Acting

Construction : Both end clevis, Foot mounting, Flange mounting,

Trunion mounting, Tie rod construction.

Bore diameter : 32 mm to 750 mm

Stroke : upto 1500 mm

Working Pressure : 150 to as per Customer’s requirement.

|

|

METAL EXTRUSION PRESS

DEEP DRAWING PRESSES

HYDRAULIC CYLINDERS

FOUR PILLAR PRESSES

POWER PACKS